“Perfect design and perfect quality is basic of successful.”

— Taizhou Xiongshi Plastic Mould Co., Ltd

Nowadays, an increasing number of people own pets, resulting in the ever-growing pet product market. In this case, more and more plastic products factory start to invest in the pet plastic products producing. So pet product mold demand is going up year by year.

§. Pet product part design.

3D part design provided by client, or create new 3D part designs based on the client’s samples. Since the samples are available in the market, we cannot simply copy them 100%. Therefore, we need to make some changes to ensure that the new design has some differences from the samples.

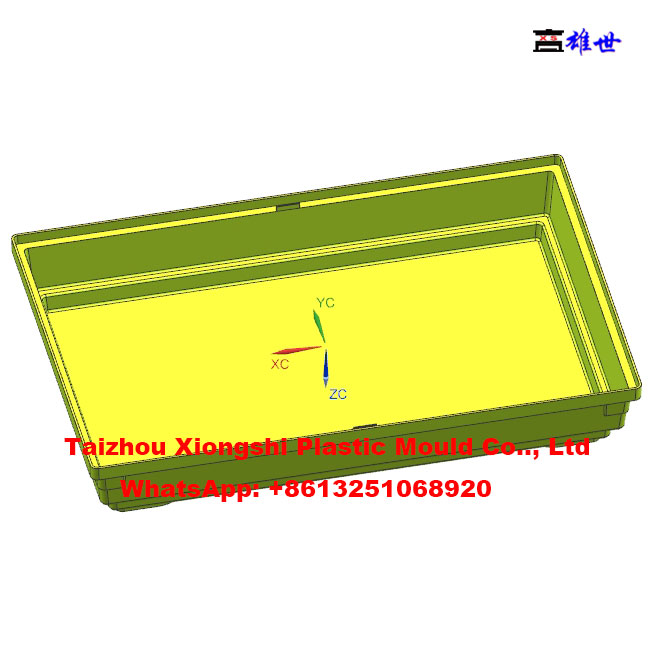

§. Pet product mold design.

Taizhou Xiongshi Plastic Mould Co., Ltd. is responsible for making 3D designs of the molds. Since the mold price already includes the cost of mold design. When the mold design is ready, it will be sent to the client for checking. Well, some clients don’t have 3D software, so we will send the design pictures to the client to take a look.

A new mould project mold design include below jobs:

- Product design analysis. Pet product normally design not complex, we can just analyse part design according experience. From the part sizes, shape, and plastic material, engineer can analyse and get the best gate size and gate position.

- Mould structure design. Include mould structure type (such as two plates mould or three plates mould), parting, filling system, cooling system, etc.

- Mold core and cavity design: Design mold core and cavity, to insure the product with good finish and high precision.

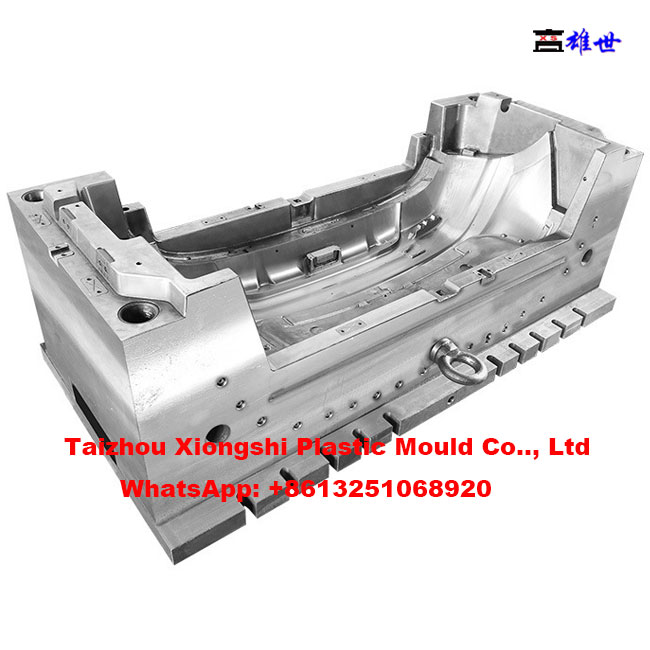

§. Mold tooling.

CNC milling tooling is main rough tooling for most mould. Most pet product mold use CNC milling tooling as rough tooling.

Pet mold tooling process same with commodity product mold. Mainly include CNC milling tooling, hole drilling, CNC engraving tooling, deep hole drilling, EDM, etc.

§. Pet product mold test

Need to prepare the plastic raw material and color before mold test. Most of pet product made with PP material. PP new material doesn’t need to be heated before injection molding, but lots of plastic material such as ABS, PS, PC, PA, etc. have to be heated and then can be used to produce the parts.

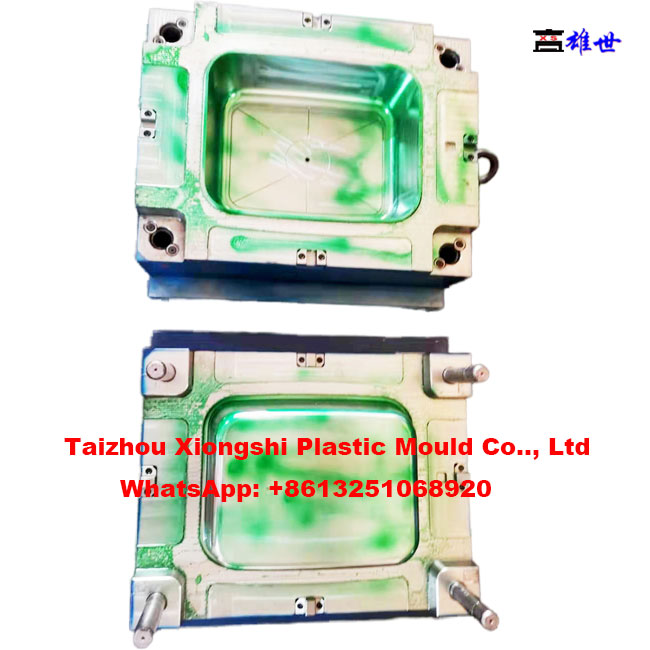

§. Pet product mold pictures.

Some pet product molds need high shinning polish finish. Which detail surface finish needed, need client to tell us during molds quotation. Because some polish job need to be done by manual, long time and high cost.

§. Pet product mold packing and delivery.

Pet product mold packed with export standard wooden case. More than 90% of our factory molds exported all over the world. So we know very well about how to pack the molds.

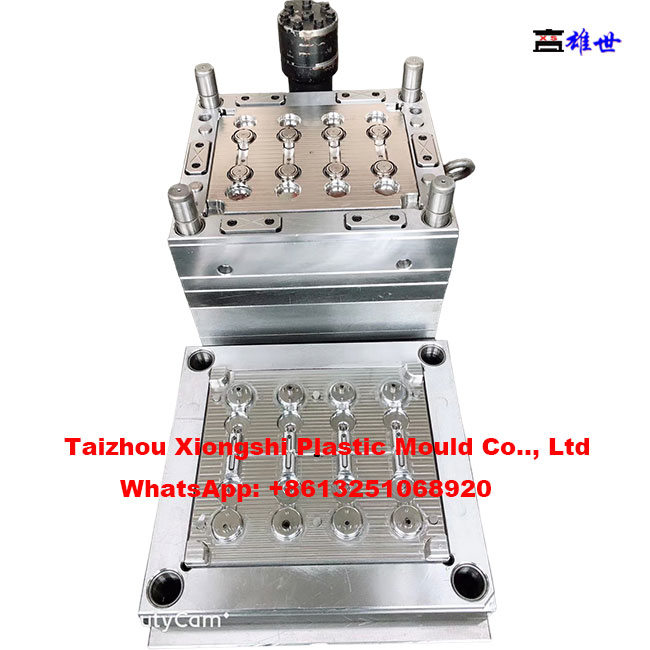

§. Recommend other product moulds made by us.

Our main product include cap mould, preform mold, bucket mould, cutlery mould, cable tie mould, stool mould, office chair mold, automotive part mould, goggle mould, scooter mould, etc.