Taizhou Xiongshi Plastic Mould Co., Ltd have rich experience in making pet carrier mould. High quality, short delivery time, comfortable service is our company mottos. Without them, same like fish without water. Pet product mold is our main production line. Welcome to contact us.

| Item no. | Name | Detail |

| 1 | Pet carrier plastic material | PP |

| 2 | Pet carrier plastic material shrinkage rate | 1.5% |

| 3 | Pet carrier 3D part design | Client provide sample or Taizhou Xiongshi Plastic Mould Co., Ltd. buy sample from market, and make some changes on the design based on the sample. |

| 4 | Pet carrier DFM report | Mould is simple, no need DFM analysis. |

| 5 | Pet carrier mould 3D design | Provided by Taizhou Xiongshi Plastic Mould Co., Ltd, confirmed by client. We provide mould design pictures with detail sizes for the client who can not open mould 3D design on computer. |

| 6 | Pet carrier mould steel | Core and cavity P20H, or 45# forging steel. Mold base 45# steel. |

| 7 | Pet carrier mould runner system | Cold runner or hot runner. |

| 8 | Pet carrier mould test | Mold test cost include in the mold price. Courier charge beared by us or discussing during quotation stage. |

✔ Pet carrier plastic material

Choose the right plastic raw material is very important for the pet carrier injection molding. Normally pet carrier made with PP material, but need to analysis product wall thickness.

✔ Pet carrier plastic material shrinkage rate

Normal PP materiak shrinkage rate is 1.3%-1.7%. When design the mould, need client to provide us this material specification to make sure the detail value of the material shrinkage rate which will use for mass production. In case client can not provide this information. We will use the middle value (1.3%+1.7%)/2=1.5% as the mould shrinkage rate.

✔ Pet carrier 3D part design

New design

2023 new design

Fashion design

2023 new design

Fashion design

2023 new design

Fashion design

Client can provide us pet carrier samples to copy and modify the design slightly according request. Of course, we provide design service which design complete new, but design cost is high. Before start the design job, have to discuss on the detail about the part design and cost.

✔ Pet carrier 3D print samples

pet carrier mould

To preclude assembly issues and visual disparities between computer designs and actual products, 3D printing samples of all newly designed products need to be fabricated for examination.

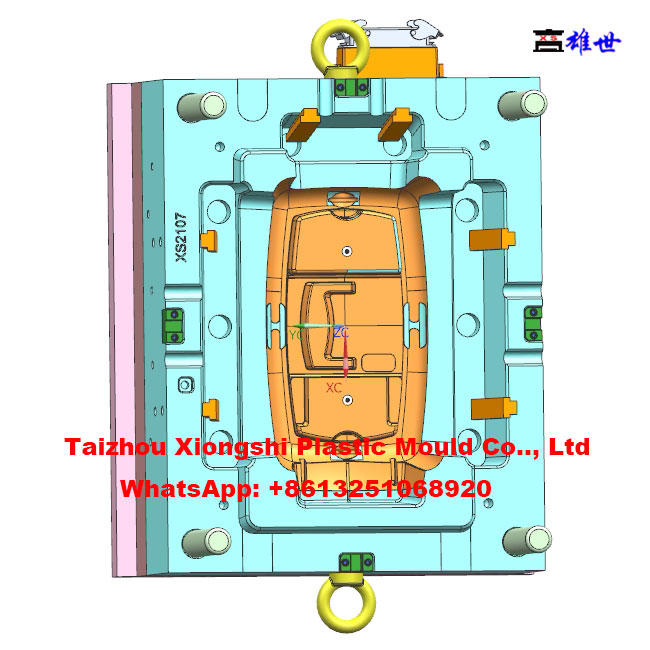

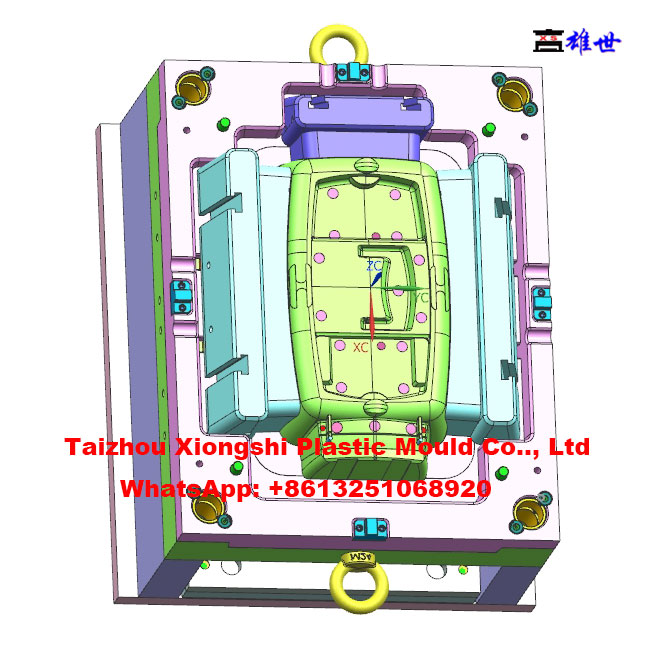

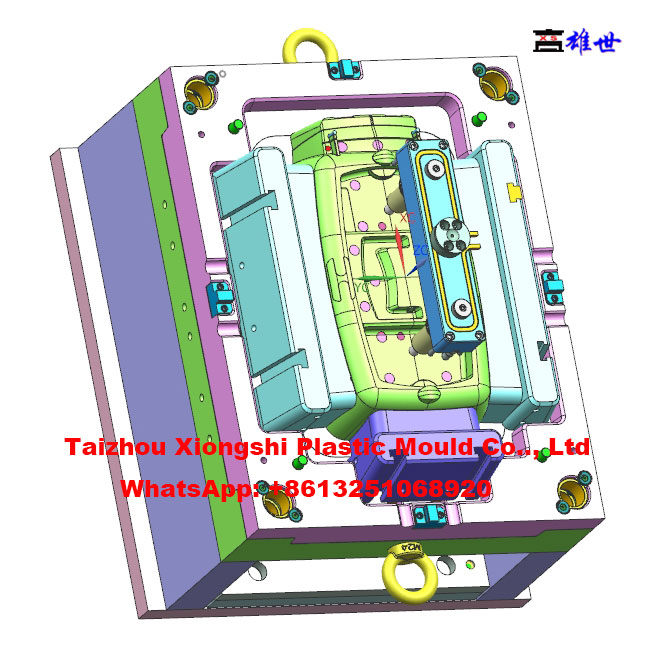

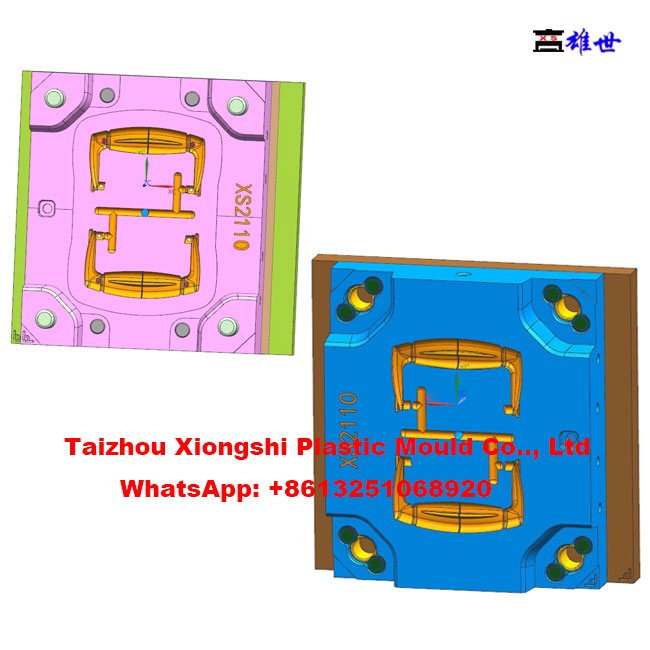

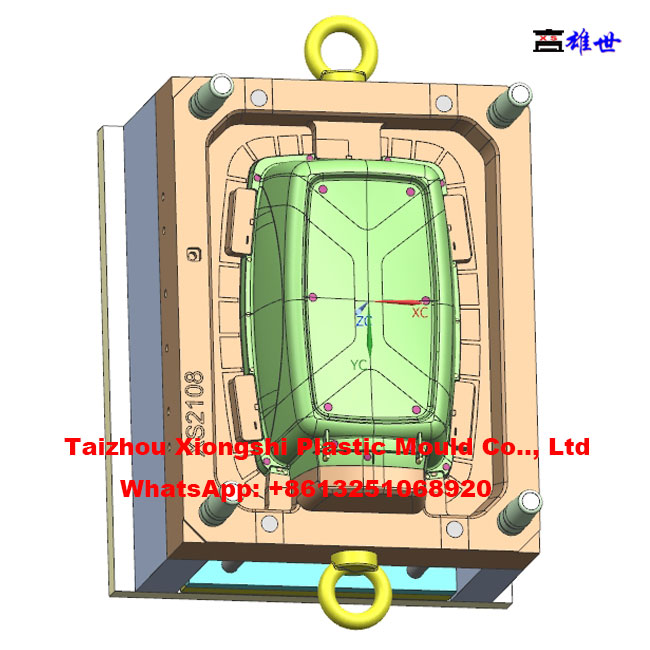

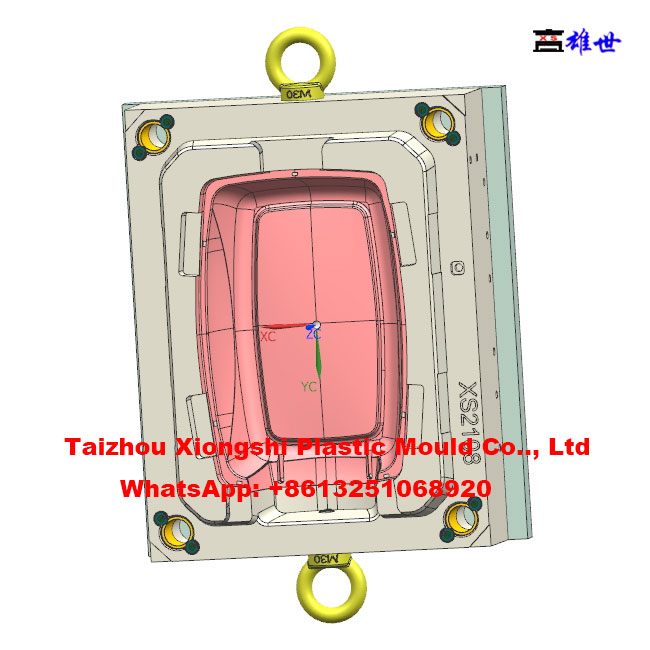

✔ Pet carrier mould 3D design

After part design got done, we can go on the mould 3D design. Due to pet carrier moulds are simple, so there is no necessary to do the DFM analysis. Of course, if client think have to make the DFM analysis, we will be definitely provide this service.

✔ Pet carrier mould steel.

Same like other pet products mould, pet carrier mould core and cavity made with P20. But if your production quantity not more than 100,000units, 45# forging steel is a better choice. Because mould life already met your target request, but mould price much cheaper. So can save many money to develop other products mould.

✔ Pet carrier mould runner system.

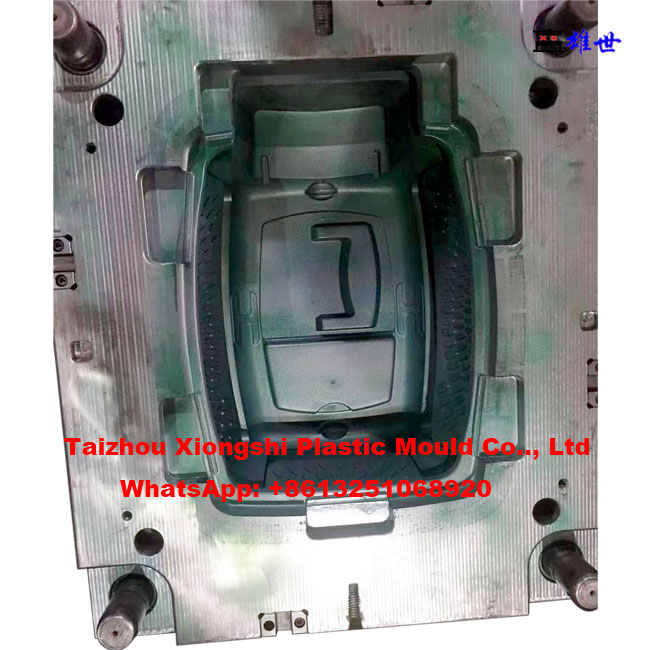

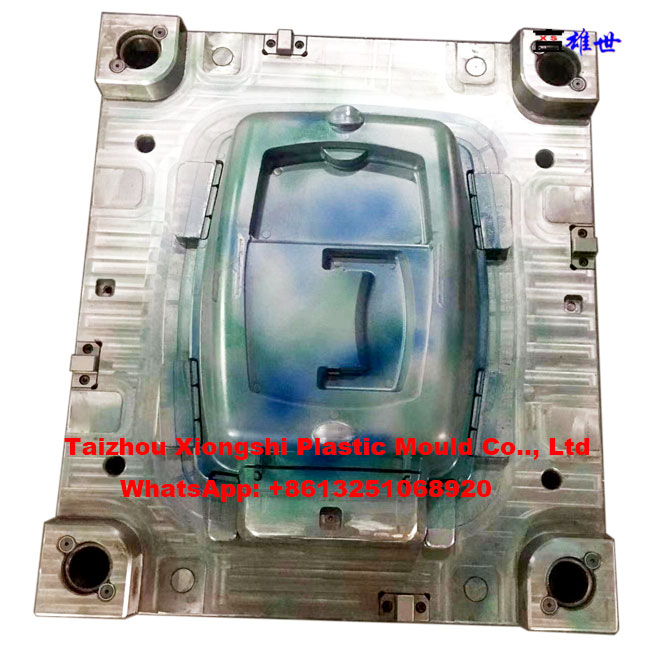

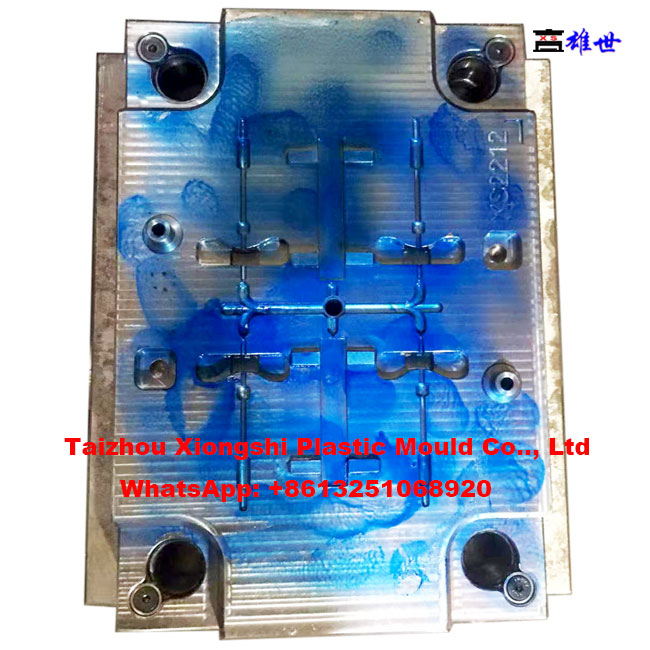

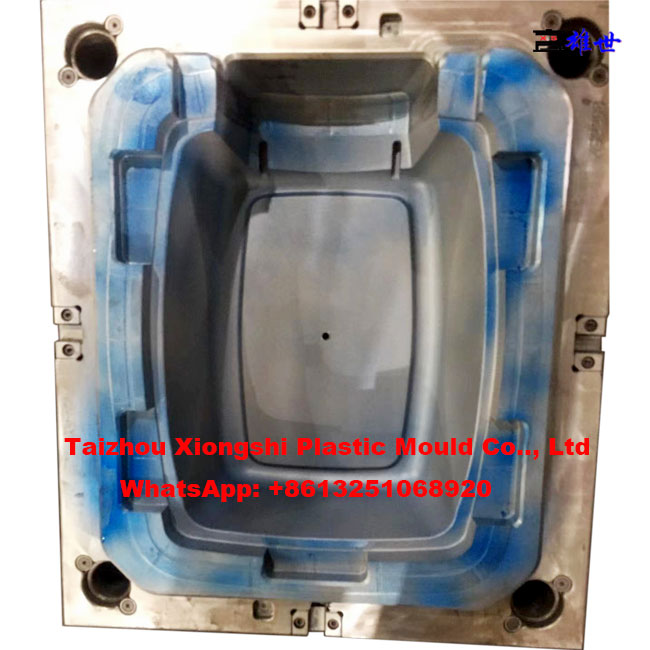

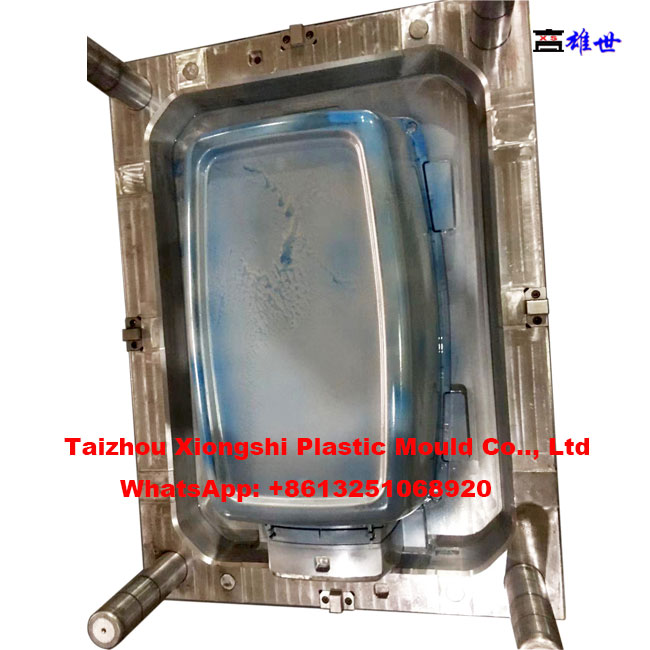

This product include some plastic parts, include base, cover, handle, lock parts, cover plate, door, etc. Each part mould need to consider to design the mold with cold runner or hot runner, which runner system is better. According actual project, some big parts mould made with hot runner, such as base part mold and cover mould. Small parts moulds are all made with cold runner system.

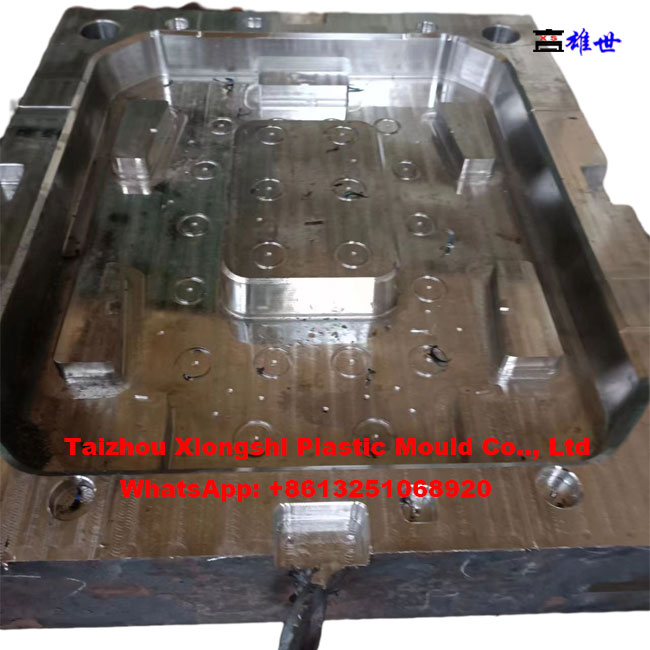

✔ Pet carrier mould machining.

Pet carrier mould CNC milling tooling is the main rough tooling process. The tooling process include grinding, hole drilling, deep hole drilling, CNC milling tooling, CNC engraving tooling, etc.

After CNC milling tooling, pet carrier mould will go on the hole drilling tooling.

Mould holes position already marked during CNC milling tooling process. In this way, holes drilling will be no mistake occured.

Mould plates of pet carrier mould finished CNC milling tooling.

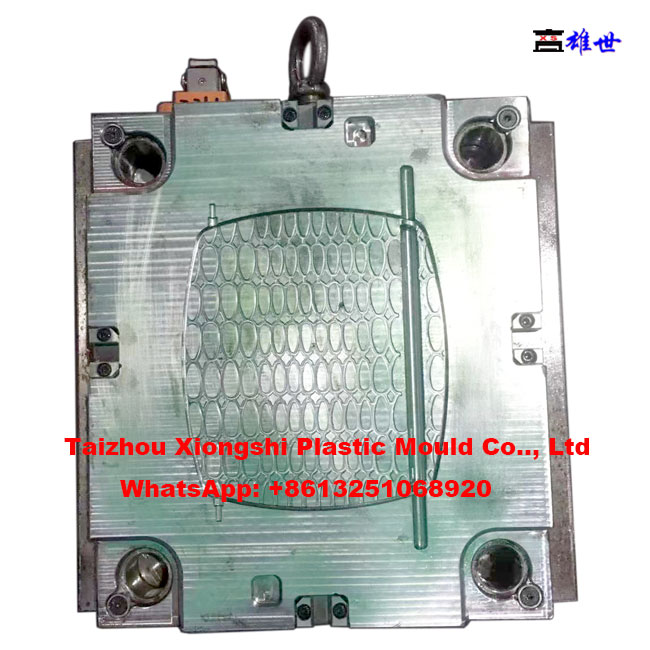

High speed CNC engraving tooling is main precise machining for pet carrier mould. High speed CNC engraving tooling is one of high precise machining for plastic injection mould. Compare with normal CNC engraving tooling, high speed engraving tooling have much higher precision.

✔ Pet carrier mould runner system.

Most of the pet carrier moulds use hot runner system for better hand touch and visual perception. We only use high quality hot runner system, which we have cooperated long times.

There are two types of hot runner temp. controller. One is normal. Another one drawer type. The advantage of drawer type temp. controller is that easily to replace the damaged zone with new. Secondly, drawer type can support wider voltage change.

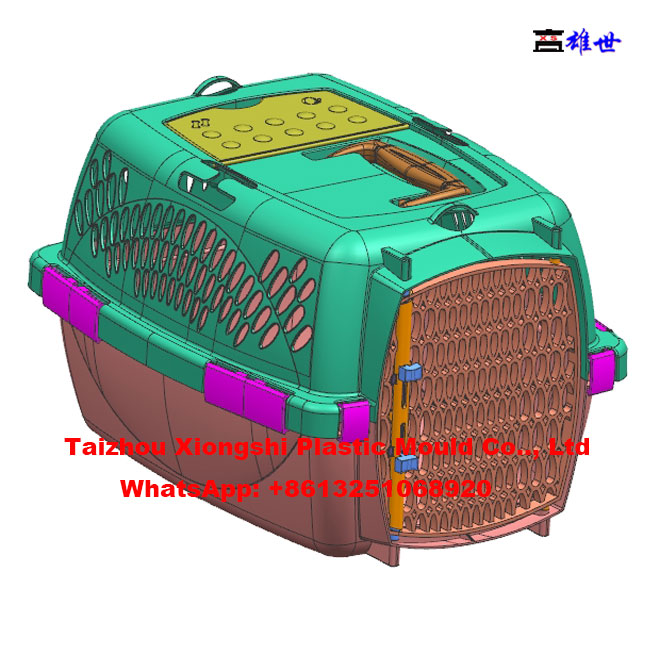

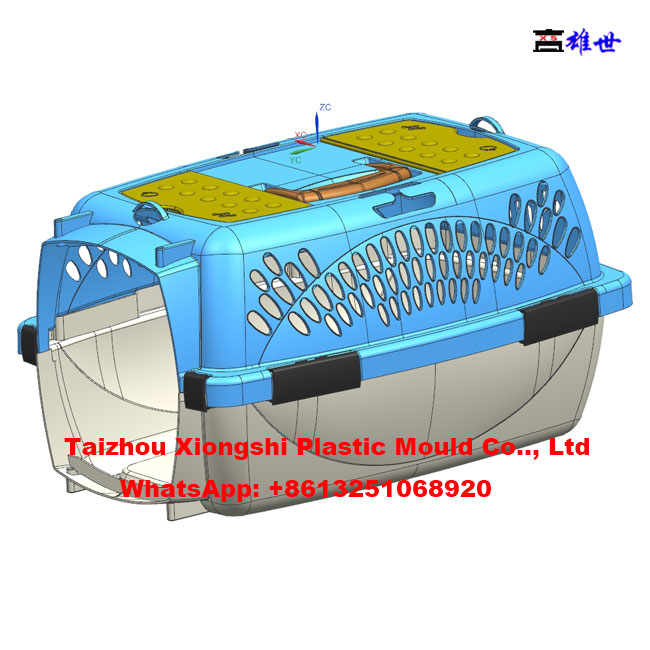

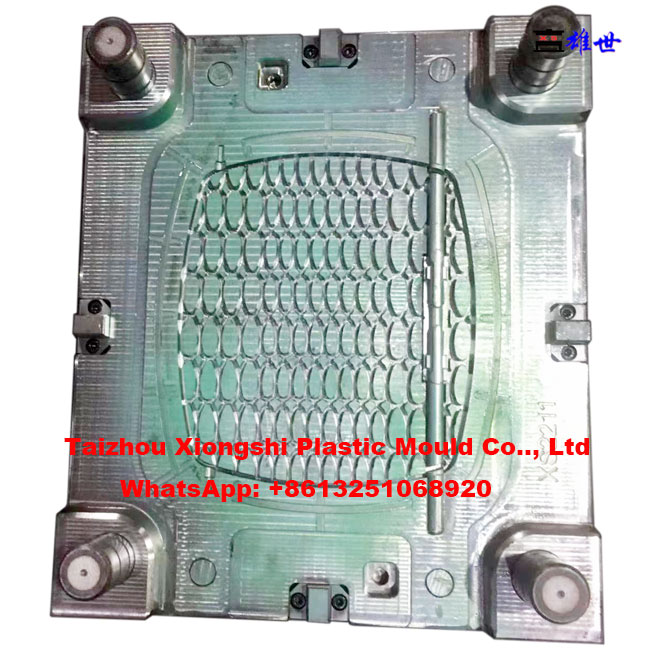

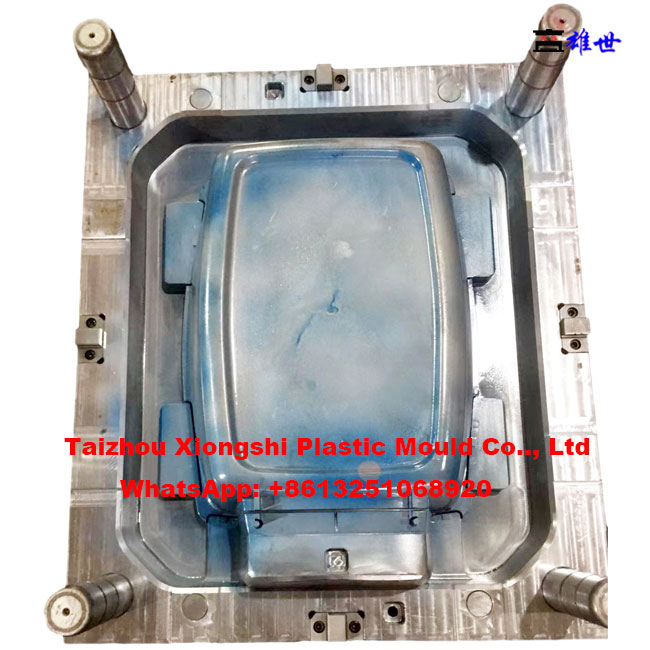

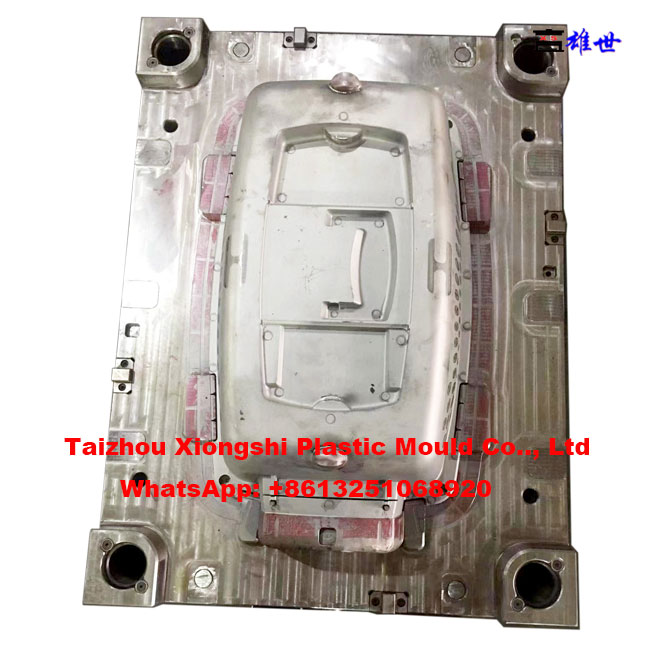

✔ Pet carrier mould pictures show.

✔ Pet carrier mould test.

Mould test cost included in the mould price. But in the case client need to change the product design and modify the mold, client need to pay for the extra mold test.

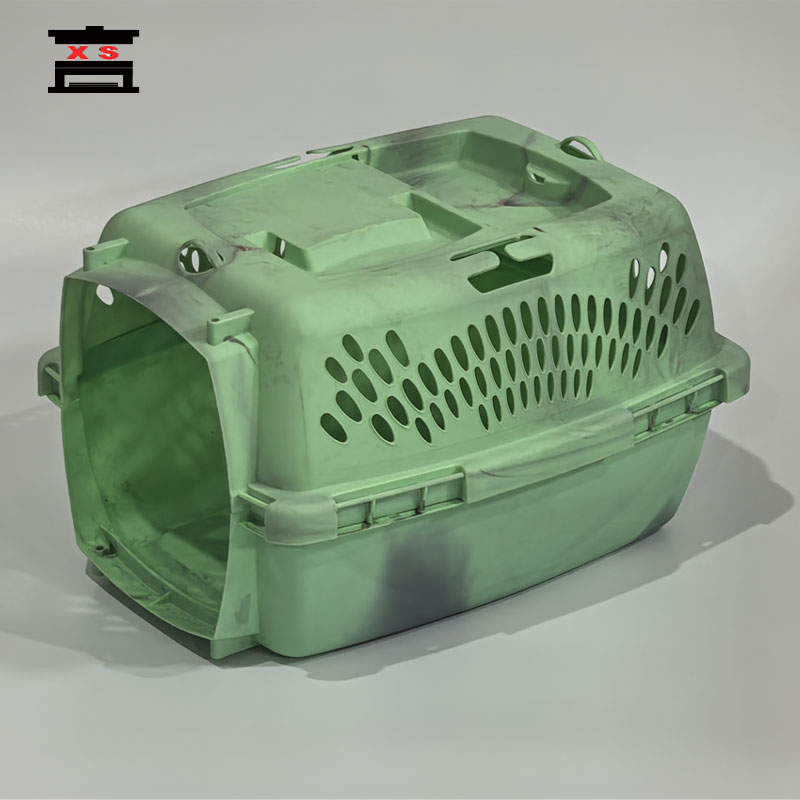

✔ Pet carrier mould test samples.

Cat Litter Box Dog Toilet Pet Product Mold

Add.:Huangyan District 318020

Taizhou City, Zhejiang Province

China

Email: sales@xsplasticmould.com; whatsApp&wechat: +8613251068920